A Westfield-based company that manufactures safety restraints has unveiled a new safety system for emergency medical services personnel that will better protect them in ambulance compartments.

IMMI, which has its headquarters in Westfield, conducted a live ambulance crash demonstration March 16 at its Center for Advanced Product Evaluation, or CAPE, which is off 191st Street. CAPE is the testing and validation center for commercial vehicles in North America, company officials said.

IMMI created MBrace, an airbag protection device that deploys to protect a person’s head and neck in a frontal crash or rollover. The device includes a crash sensor that triggers an airbag deployment in a fraction of a second, according to company officials.

MBrace is also equipped with four retractors, which allows for freedom of movement while keeping an EMT safely buckled, according to the company The Centers for Disease Control and Prevention estimates that the fatality rate for EMS workers was more than two times the national average for all workers in traffic accidents, company officials said.

The company’s safety products can be found worldwide on car seats, heavy trucks, school buses, recreational/off road, military, fire/EMS, motor coach and construction vehicles.

“After five years of research and development, we’re excited to launch this groundbreaking innovation in advanced safety to better protect the men and women who work every day to save lives transporting patients in ambulances,” said Larry Gray, CEO of IMMI. “IMMI is excited to offer a new solution for these heroes which aims to decrease fatalities and injuries.”

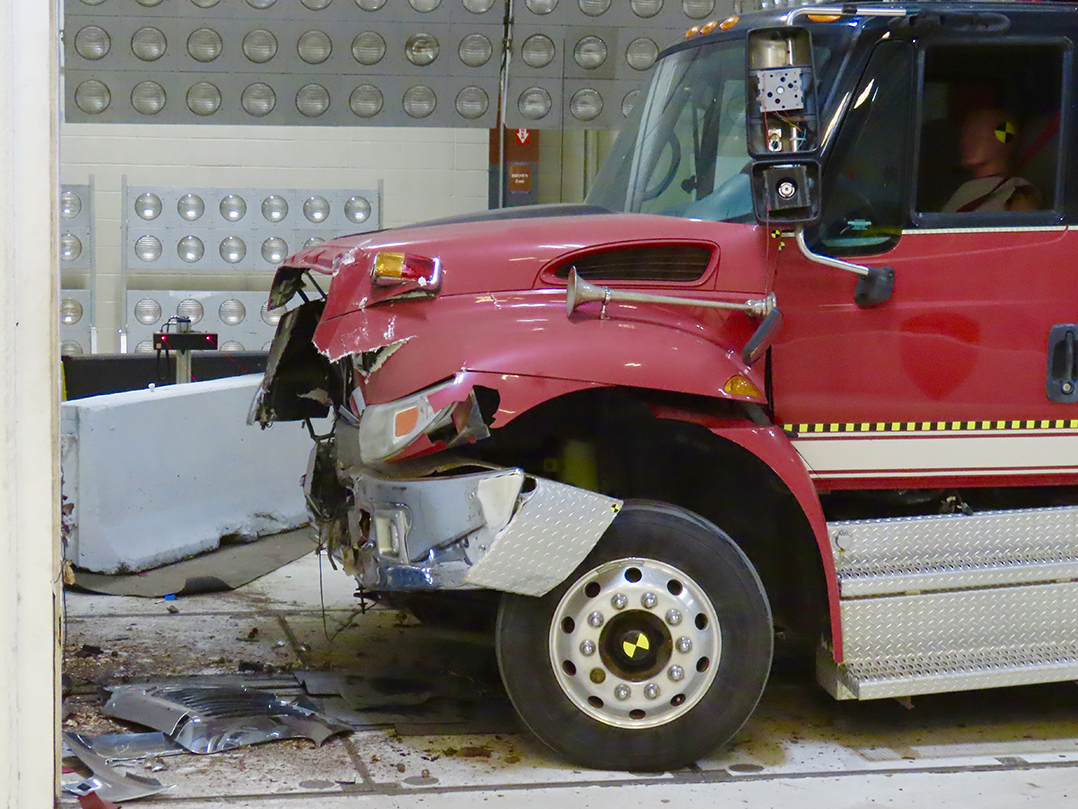

About 200 individuals consisting of fire and police personnel, manufacturers and dealers, along with several members of the media, were invited to the ambulance crash test. The crash involved an ambulance traveling 27 mph with dummies inside traveling down a makeshift track inside the CAPE that slammed into a concrete wall.

Nicolas Awabdy, vice president of engineering at IMMI, said the CAPE performs crash tests on a regular basis that take hours of preparation. Ambulances and other vehicles that are used for testing are equipped with data acquisition units and several cameras, which help company officials make any necessary adjustments to safety equipment that may be required after performing an analysis, Awabdy said.

High-powered lights are also used, in addition to high-speed cameras that capture different frames per second as part of the data collection process, he added.

“If it wasn’t for the high speed and events happen so quickly and the occupants are moving so fast, we couldn’t really bring it down to what it really looks like in slow motion,” Awabdy said. “That slow motion helps immensely as we try to understand how advanced safety works.”

The Mbrace safety system is designed for side-facing occupants and has been several years in the making, Awabdy said. The company has worked on the design and development while working with customers in understanding how to bring the safety feature to the back of an ambulance, he added.

IMMI plans to roll out the Mbrace safety system to the market in the next few months, according to Awabdy. He said the safety system is important since ambulances can be involved in accidents at high speeds.

“It’s so important that we’re bringing that next level of safety to protect EMTs and trying to protect those who have actually been in other accidents,” Awabdy said.

The Mbrace safety system will be installed in new ambulances, but it is possible it could be made as an after-market device, according to Awabdy. Testing for the safety system has occurred over several years that first involved developing the airbag and then bringing vehicles in for further testing, he added.

Six vehicles had previously been crashed prior to the March 16 test, which Awabdy said has helped the company with the design and development of its safety system equipment. In addition, the tests have also helped IMMI make any necessary adjustments that need to be made along the way while looking at different size occupants and various crash scenarios.

Awabdy said the company is also considering the safety system for military vehicle use.

“We’ve also considered maybe there’s opportunities in construction or off-highway markets where airbags are not standard equipment today,” he said.

About IMMI

IMMI was founded in 1961 as Auto-Safe and started with four employees and two sewing machines.

For 62 years, IMMI has been a leader in developing, designing, testing and manufacturing innovative safety restraints and systems. Its safety products are found worldwide on car seats, heavy trucks, school buses, recreational/off road, military, fire/EMS, motor coach, and construction vehicles.

Headquartered in Westfield and operating seven additional global facilities, IMMI is also home to CAPE, the world’s leading state-of-the-art testing facility.

Corporate headquarters: 18881 IMMI Way, Westfield

Employees: 1,800 worldwide

Website: imminet.com